The family of foam materials is a Large category that can be defined in several ways and shapes. Any foam material can easily be either open cell foam or closed cell foam for you.

In a short time, it might be difficult for you to understand just what they are. But you’ll easily find out what open cell foam is and what closed cell foam is after reading through this report. You can get to know the contrast between the 2 different forms of foam material, and you can choose wisely for your applications, another benefit.

Polyurethane foam open cell

Foam products are flexible, lightweight and robust, which makes them suitable for use in many sectors.

What is the Open Foam Cell?

We will create open cell foam materials from some aspects in depth here.

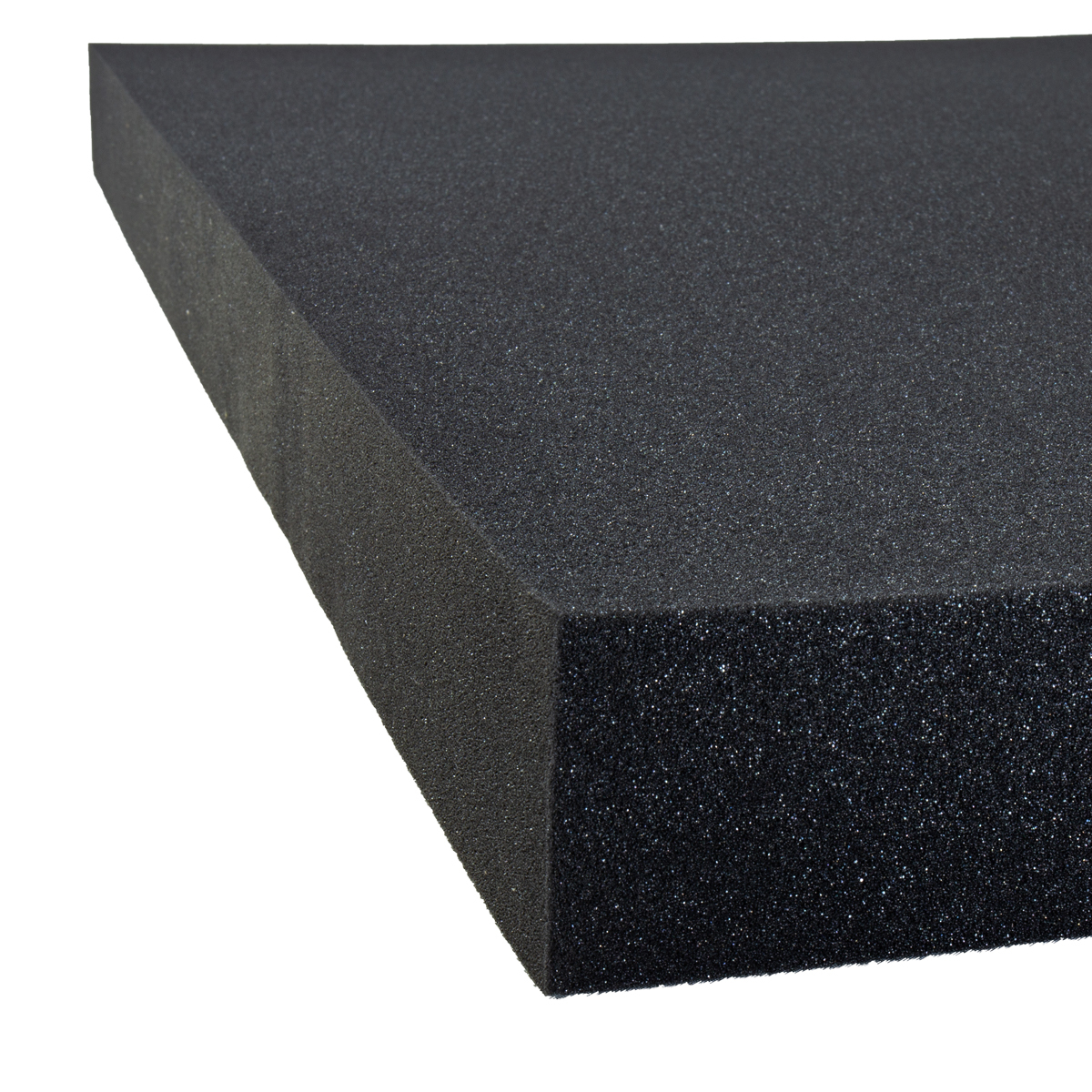

Polyurethane Foam with Black Open Cell

One of the most frequently-used open cell foams is polyurethane foam. They are commonly used in a variety of industries and products in the application of insulation, sound and shock absorption, including furniture upholstery, seat cushions, medical packaging, electronics, power equipment, and so much more. Open cell Polyurethane foams, because of their dexterity and oxygen resistance, are superior to other types of insulation.

You might be puzzled to learn that the Polyurethane foam is often made of something solid. The truth is that there are two types of polyurethane foam-open cell or closed cell structure, both of which vary in densities and applications. However, we are concentrating on open cell polyurethane foam materials in this article.

In addition, the open cell structure can also be supplied with polyurethane foam. For open cell foams as well, PVC/ Nitrile foam and EPDM foam rubber are available.

EPDM Foam Open Cell

Open cell foams take Polyurethane foam sheets as an example of where the cells within the substance have been split, allowing the spaces within to be filled by air. Compared to closed cell foams, open cell foams are usually lightweight and less bulky, and have a smooth, cushioning and sponge-like look.

The gas bubbles used in its development are released into the atmosphere during the expansion and curing of open cell foams, as opposed to being frozen in place as with closed cell foams. Inside open cell foams, these holes allow them to interlock and interconnect. Owing to this porous existence, liquid water or water vapor cannot be resisted by open cell foams.

What are open foams made of cells?

Open cell foam materials are available, but they are usually made of polyurethane, reticulated polyurethane, PVC/nitrile, EPDM rubber, etc.

Open Cell Foam FEATURES AND ADVANTAGES

Foam for soft open cell memory

Some of the open cell foam’s characteristics and advantages include:

It contains no volatile organic compounds or gases that deplete ozone.

It is suitable for minimising the transmission of noise

It contains little to no residual particles and traps in its pore spaces most foreign particles, making it suitable for dust and allergen reduction.

It is immune to mold formation.

It’s perfect for sound proofing,

It has a strong value of approximately R-4.21 per inch of insulation

This accounts for about 40-50 percent of apartments ‘heat gain/loss

It is stable and will not break, decrease or decrease over time.

It has a high potential for expansion, capable of rising up to 100 times

It has a low density of between 0.4 and 1.2 lbs./ft3/ft3/ft3/ft3/ft3

USES OF CELL FOAM OPEN

Custom Foam Packaging and Polyurethane

For a broad range of construction purposes, open cell foam may be used, including:

Low-cost upholstery for furniture

Projects in interior design

For buildings, sound proofing

Protective Packaging for Foam

Permeable vapor, humidity and air needed for application

What is the Closed Foam of Cells?

A solid, flexible plastic rubber material that is made up of internal pores or cells is closed cell foam. These closed cell foam internal cells sit closely together but are not related. A net filled with bubbles, where the balloons are tightly trapped against each other, can be compared to a closed cell structure, but each of the bubbles is not interconnected.

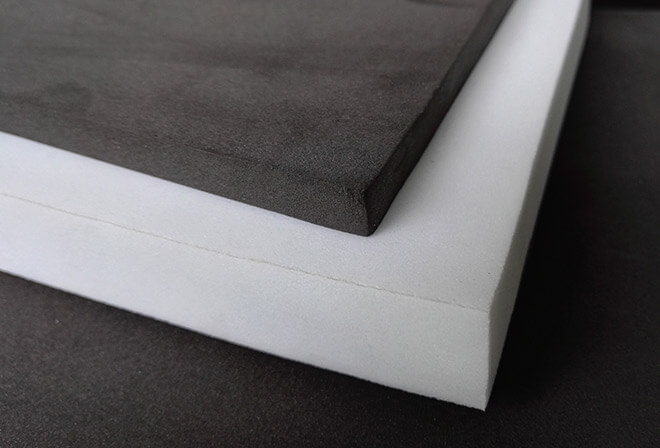

Sheets for Closed Cell Foam

Closed cell foams from various industries such as construction, packaging, marine, electronics, automotive and so on are now used more frequently. EVA foam, polyethylene foam, neoprene foam, PVC/nitrile foam rubber, SBR foam rubber and so on are the usual closed cell foam products.

What are closed cell foams made from?

Polyethylene Foam Sheets Closed Cell

The materials that can be used to manufacture the closed cell foam differ significantly from EVA, polyethylene, polystyrene, polypropylene rubber, etc. The closed cell foam mainly contains a trapped gas bubble that is formed during foam expansion and healing. A blowing agent constitutes these bubbles. They are permanently locked to a spot, as the trapped gas is very successful in increasing the foam’s insulation power. The foam that is produced is solid and typically has a medium density that allows the gas bubbles to lock into place. The design of the foam makes it possible to withstand liquid water and to be vapor-retardant.

CLOSED CELL FOAM Characteristics And ADVANTAGES

Foam Sheets Black Closed Cell

The characteristics and benefits of the foam of the closed cell include:

Useful and highly reliable in both exterior and interior settings.

Helpful in increasing the power of structure

Great for heat and sound insulation provision

Reduce vapor transmission effectively

Superior barrier for moisture

Excellent leakage resistance

CLOSED CELL FOAM APPPLICATIONS

Cutting Custom Closed Cell Foam

The closed cell foam has a number of applications. For a variety of applications which require moisture & shock resistance and heat & sound insulation, they can be very useful. Closed cell foam as well as sponge rubber products have been highly popular for years with the application of insulation, cushioning, padding and gasketing. And the closed cell foam applications are infinite. It is often used to securely store and present delicate jewelry, instruments and electronics etc. as a form of custom foam safe packaging. They also provide excellent protective cushioning, moisture and air resistance, which prevents moisture from accumulating within the box, making it the best alternative for longer periods of time to safely store delicate machinery.

Typical closed cell foam applications include:

Construction and construction insulation and sealing

The HVAC system and appliances

Thermal insulation and absorption of shocks

Seals and cabinets for the enclosure

The disposables for medical use

Gas and oil equipment

Aircraft and Aerospace

Automotive and transportation

COMPARISON Between Open Cell Foam & Closed Foam of Cells

A kind of cellular product is foam materials . The configuration of its cells and, in particular, the contents of its cells, whether open or closed, will have a major effect on the product’s output and final applications.

While open cell foam and closed cell foam may have similar appearances, because their properties and performance are completely different, they should be viewed as two different items.

Open Cell Foam, Flexible and Soft

Although closed-cell foam contains more than 90 percent closed cells, the figure is typically below 20 percent for open-cell foam, of which there is no official description yet, although it may have higher proportions. Indeed, open cell and closed cell foam have some common features, such as shock absorption, thermal insulation, deadening of noise, etc. In general, the distinguishing feature is that the “Closed Cell Content (CCC)” specifically affects the basic properties of the foam, such as tear strength, thermal conductivity, average density, water absorption and watertightness, permeability to vapor or compressive strength.

The key differences between open cell foam and closed cell foam can be found out as below:

Structure of foam

Polyurethane Foam Reticulated

The most evident difference between closed cell foam and open cell foam is apparently the distinct foam structure. With small closed cells, closed cell foam is formulated and presents a good, solid appearance. Yet open cell foam shows an irregular and lightweight appearance, so that the open cells around the open cell foam materials can be easily discovered.

Density of Foam

EVA Foam Insert for Mid Density

In contrast with open cell foam, closed cell foam is typically high in weight. Closed cell foam has a closed cell structure and before foaming, they can retain almost their initial weight, but open cell foam can not cope with that. After the foaming process, the open cell structure releases a significant portion of its weight.

Moisture, Breeze, Resistance to Liquid

Closed Cell EVA Foam Rolls in Green Color

You can take another fast and smart approach when you want to differentiate closed cell foam from open cell foam. By merely pouring some amount of water on both types of foam materials, it is simple and quick. Suddenly, you will figure out that one form of foam absorbs water and brings water into the small cells. But the rest do not absorb water from their surface and hold water out of it. So you may now know that the first is open cell foam, and the other is closed cell foam.

The voids intersect each other in the open cell foam, creating pathways through the solid. Closed cell foam consists of individual closed areas, so this kind of foam can not be penetrated by air or liquid. In the face of moisture, water, air and other liquids, they have different output due to their foam structures.

Cost of Content

In general, open cell foam involves a lower cost of material in use. Polyurethane foam and reticulated polyurethane foam are the most common open cell foam materials. They have been widely used for furniture upholstery, seat cushion, carpet underlay, foam filters, partially due to their low cost. Although closed cell foam generally offers better insulation efficiency and longevity, it also contributes to a higher cost of content.

Sound Insulation and Thermal Insulation

Egg Crate Open Cell Convoluted Foam

Closed cell foam materials will usually outperform open cell foam materials when considering heat insulation. Closed cell foam has lower thermal conductivity, such as polyethylene foam, meaning that roofing and flooring isolation applications can be commonly used. But open cell foam, meanwhile, can give excellent sound absorption compared to closed cell foam. Since they have several small open cell structures, they can be very efficient and effective in receiving lots of external sound or noise. For broadcasting studios and meeting rooms etc., you can find open cell convoluted PU foam used as sound proof foam.

Various Implementations

Open Cell Foam Custom Cutting

Generally, open cell foams are soft and compressible. Open-cell foams serve as a good insulating air trap within the cells. In their cells, foams with open cells, such as a sponge dish brush, are able to absorb the liquid. Closed cell foams can have greater structural rigidity and the cells can be filled with gases other than air during processing since the cells are closed. To prevent water or air from moving from one place to another, closed cell foams may be used. Open cell foam, especially for sponges, is also sometimes used for its absorption properties. Open cell foam is also used because of its low cost benefit in a number of insulation applications. For sound dampers, shock absorbers, cushioning, and pillows, open cell foam may also be used.

As its closed cell structure does not absorb water and trapped air is energetic, closed cell foam is also used in flotation devices. And in other applications that need water resistance, such as neoprene suits, pads, gaskets and insulation, Closed Cell Foam is also used. It is denser than open cell foam and more costly to manufacture in general.

Packaging of Closed Cell Foam

TIPS & GUIDES TO Pick Correct FOAM MATERIALS

Do you like foam that’s waterproof? Go for Closed Foam Cell

Do you want great foam soundproofing? Go for foam with open cell foam

If you have a restricted foam budget? To first see if it is workable, go for open cell polyurethane foam

Do you like foam with outstanding thermal insulation? Go for Closed Foam Cell

If you like foam with outstanding longevity and resilience? Go for Rubber Foam Closed Cell

TYPICAL OPEN CELL FOAM MATERIALS & CLOSED MATERIALS OF CELL FOAM

We list some common foam materials here, divided into two types:

Open Cell Foam: Polyurethane Foam, Polyurethane Foam Reticulated, Nitrile Foam Open Cell, EPDM Foam Open Cell

EVA Foam, Polyethylene Foam (EPE Foam, XLPE Foam), PVC Foam Rubber, Neoprene Foam Rubber, SBR Foam Rubber, PVC/ Nitrile Foam Closed Cell, EPDM Foam Rubber Closed Cell Foam

So now, we hope you can easily choose between open cell foam and closed cell foam next time. If you have any more concerns, just feel free to let us know.

Related Article: