With the continuous development of modern technology, the field of materials science continues to advance, providing more high-quality, high-performance material options for various industries. Among them, multi-density multi-layer EVA (ethylene-vinyl acetate copolymer) Block material is gradually becoming the new favorite of the industry with its unique physical properties and wide range of applications.

Multi-Density Multi-Layer EVA Block

1. Introduction to multi-density multi-layer EVA Block materials

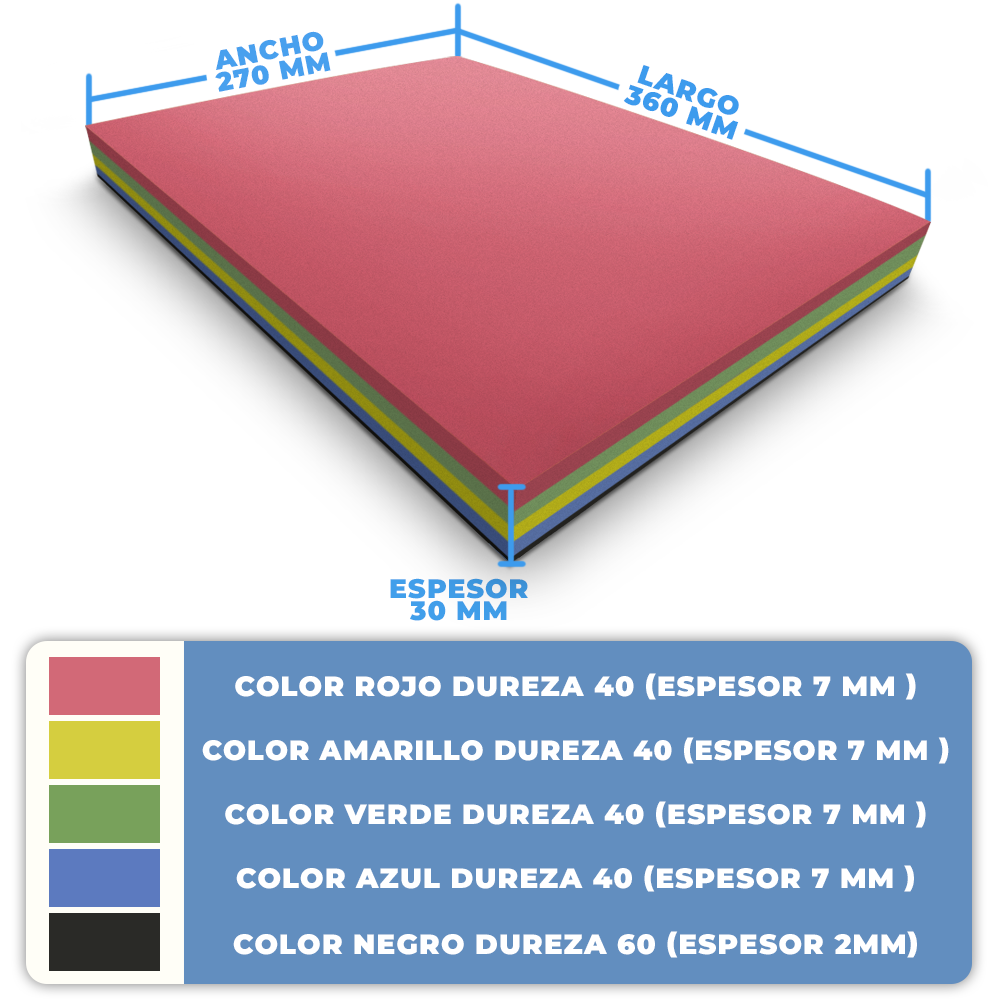

Multi-density multi-layer EVA Block material is a composite material composed of EVA layers of different hardness and density through a special process. This material combines the advantages of EVA such as lightness, softness, water resistance, and impact resistance. At the same time, through multi-layer structural design, different areas of the same material have different physical properties. This makes the multi-density multi-layer EVA Block material excellent in withstanding pressure, dispersing impact, and providing support.

2. Manufacturing technology and process

Material preparation: First, prepare EVA raw materials of different hardness and density according to product requirements and design.

Stacking combination: EVA layers of different hardness and density are stacked and combined according to the design requirements to ensure that each layer can achieve the best performance.

Hot pressing molding: Using hot pressing equipment, under high temperature and pressure, the EVA layers are tightly combined to form one body.

Cooling and shaping: After hot pressing, cooling is performed to stabilize the internal structure of the material and achieve the expected physical properties.

Post-processing: As needed, the formed materials are cut, polished, labeled and other post-processing to meet the requirements of the final product.

3. Application analysis

Multi-density multi-layer EVA Block material is very suitable for making products that require different support and cushioning properties in different areas due to its unique physical properties and manufacturing process. The following are several typical application scenarios:

Insoles and shoe materials: Multi-density multi-layer EVA Block material can provide personalized support and cushioning to meet different foot types and sports needs. It is widely used in sports shoes, orthopedic shoes and other fields.

Packaging materials: Its excellent impact resistance and shock-proof properties make it an ideal packaging material that can effectively protect products from damage during transportation.

Automotive industry: In terms of car seats, floor mats, etc., multi-density multi-layer EVA Block materials can provide a comfortable riding experience and good sound insulation effect.

Construction field: Its excellent performance has also been widely used in building sound insulation, floor cushion, etc.

4. Conclusion

Multi-density multi-layer EVA Block materials, with their unique physical properties and manufacturing processes, provide more high-quality, high-performance material options for various industries. With the continuous advancement of science and technology and the continuous expansion of the market, it is believed that this material will play an important role in more fields and bring more convenience and comfort to people’s lives.