Foot health is a critical aspect of overall well-being, and custom heat moldable orthotic insoles have become an essential tool for professionals in the industry. Whether you’re running a podiatry clinic, managing a medical institution, or working with sports brands and shoe manufacturers, having the right insoles can make a world of difference in terms of comfort, support, and performance.

At Ideastep, we specialize in providing high-quality, customizable orthotic solutions designed for foot care professionals and footwear manufacturers. Our CSS757 Heat Moldable Insoles are engineered with advanced thermoplastic materials, allowing for a precision fit that enhances both support and foot alignment.

In this guide, we’ll explore the benefits of Custom Heat Moldable Orthotic Insoles for Foot Care Professionals, how they’re used, and why Ideastep’s CSS757 insoles are the go-to choice for B2B buyers.

Why Choose Heat Moldable Orthotic Insoles?

If you’re looking for insoles that offer superior customization and support, heat moldable orthotics are the way to go. Here’s why:

| Feature | Benefit |

|---|---|

| Custom Fit | Conforms to the foot shape for optimal comfort and support |

| Biomechanical Support | Helps align the foot properly, reducing strain and preventing injuries |

| Versatile Applications | Suitable for medical use, sports, and footwear manufacturing |

| Easy Modification | Can be heat-molded and fine-tuned for a perfect fit |

| Bulk Customization | Ideal for large-scale orders and OEM production |

These benefits make them an invaluable solution for foot health professionals, sports brands, and shoe manufacturers alike.

Key Features of CSS757 Custom Heat Moldable Insoles

1. High-Quality Materials

Our CSS757 insoles are available in three different material options, each designed to meet specific needs:

- TPU (Thermoplastic Polyurethane) – A softer, more flexible material that offers moderate support.

- PP (Polypropylene) – A rigid, high-hardness material that provides firm arch support.

- Hybrid Material – A blend of TPU and PP, offering a balance between support and flexibility.

2. Advanced Heat Moldable Technology

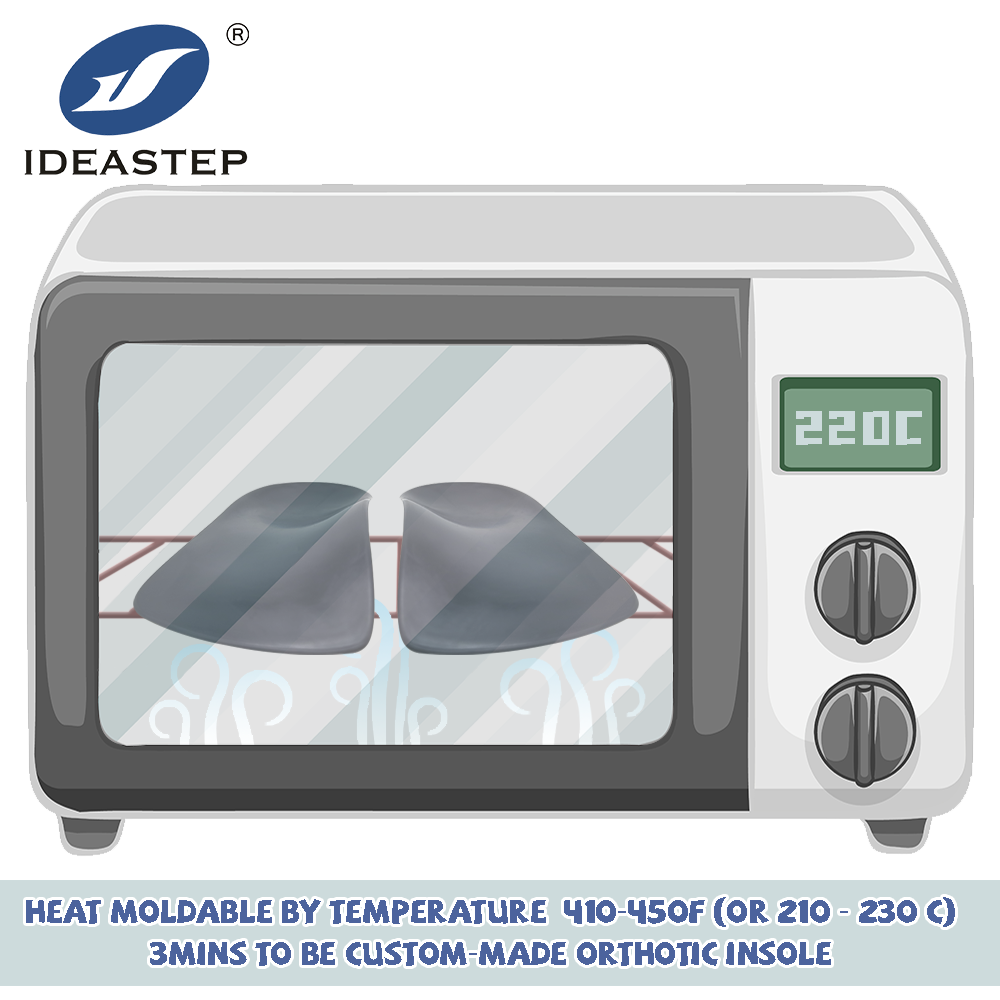

Unlike standard insoles, CSS757 can be heated to 410-450°F (210-230°C) for just 3 minutes, allowing it to be shaped precisely to a foot model. This ensures a custom fit tailored to individual needs.

3. Medical-Grade Arch Support

Designed specifically for podiatric clinics and medical institutions, these insoles:

- Provide longitudinal arch support to improve foot stability.

- Help control subtalar and midtarsal joint movement, preventing overpronation.

- Feature a deep heel cup that enhances alignment and shock absorption.

4. Easy Finishing and Customization

After molding, the insole can be ground and shaped for a precise fit. Once refined, a top cover material such as EVA foam, leather, or fabric can be added to enhance comfort and durability.

5. Suitable for Various Industries

Our heat moldable orthotic insoles serve multiple business sectors, including:

? Foot Care Industry (Clinics & Medical Institutions)

- Ideal for podiatrists, orthopedic specialists, and rehabilitation centers.

- Customizable for patients dealing with flat feet, plantar fasciitis, and foot pain.

? Sports & Fitness Brands

- Designed for sports footwear brands looking to enhance performance and comfort.

- Helps athletes maintain optimal foot positioning and reduce injury risks.

? Shoe Manufacturers & OEM Suppliers

- Perfect for bulk customization in footwear production.

- Easily integrated into custom orthopedic footwear for enhanced product value.

? Wholesalers & Retailers

- Available in bulk quantities, making it ideal for large-scale distribution.

- A great choice for retailers seeking high-demand orthopedic products.

How to Use CSS757 Heat Moldable Insoles Effectively?

Step 1: Heating the Insole

- Preheat an oven to 410-450°F (210-230°C).

- Place the CSS757 insole inside and let it heat for 3 minutes until it becomes pliable.

Step 2: Molding with a Foot Model

- Instead of placing the softened insole directly under the foot, use a foot mold for shaping.

- Press the insole onto the model to form the correct arch and heel contour.

Step 3: Grinding & Shaping

- Once cooled, the insole can be fine-tuned using grinding tools for a precise fit.

- Adjust the structure to meet specific patient or footwear needs.

Step 4: Applying a Top Cover

- Add a top layer such as EVA foam, leather, or an antimicrobial fabric.

- The insole is now ready for use in medical, sports, or custom footwear applications.

Why Choose Ideastep for Your B2B Custom Orthotic Insole Needs?

✅ 30+ Years of Expertise in Foot Orthotics

With over three decades in the orthotics industry, Ideastep continues to develop cutting-edge insole technology that meets the evolving demands of professionals worldwide.

✅ Certified by ABC (American Board for Certification in Orthotics, Prosthetics, and Pedorthics, Inc.)

We adhere to the highest standards in foot health solutions. Our ABC Certification #4290 guarantees quality, reliability, and biomechanical effectiveness.

✅ OEM & Bulk Customization Available

- Branding and customization for wholesalers and footwear brands.

- Flexible production to accommodate high-volume orders.

✅ Trusted by Clinics & Footwear Brands Worldwide

Our insoles are used by leading podiatry clinics, sports brands, and orthopedic footwear manufacturers across the globe.

What Our Clients Say

? Dr. Emily Carter, Podiatry Clinic Owner

*”The CSS757 has made a big difference in our practice. Our patients love the customized fit, and the heat-molding process is quick and simple.”*

? John Mitchell, Footwear Brand Manager

*”As a sports shoe manufacturer, we needed high-performance arch support insoles. Ideastep’s CSS757 exceeded our expectations!”*

Frequently Asked Questions

1. How long does it take to mold CSS757 insoles?

It only takes 3 minutes in the oven to reach the optimal molding temperature.

2. Can these insoles be re-molded?

Yes! CSS757 can be reheated and reshaped multiple times for adjustments.

3. Do you offer bulk orders for wholesalers?

Absolutely. We provide bulk pricing and OEM services for B2B clients.

4. What top cover materials can be applied?

You can add EVA foam, leather, or antimicrobial fabric for enhanced durability and comfort.

Get in Touch – Request a Quote Today!

- ? Interested in bulk orders or OEM services? Contact us today!

- ? Email: info@aideastep.com

Let Ideastep provide the best custom heat moldable orthotic insoles for your business needs! ?