The product and operation of EVA froth accouterments in China started fairly late, but due to the excellent processing performance and wide operation of the products, the demand has grown fleetly in recent times, attracting numerous manufacturers to enter the assiduity. Serving from the stable development of China’s manufacturing assiduity, the elevation of downstream diligence, and the development of broader operation fields, China’s EVA froth material request will maintain rapid-fire growth.

What’s EVA?

EVA is made of ethylene-vinyl acetate copolymer ( also known as ethylene-vinyl acetate copolymer), which is attained by copolymerizing ethylene (E) and vinyl acetate (VA) and is appertained to as EVA for short. Polymerization styles include high-pressure bulk polymerization, result polymerization, conflation polymerization, and suspense polymerization.

What’s EVA used for?

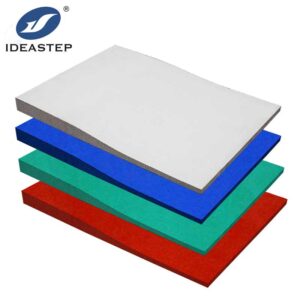

EVA patches can be produced into colorful types of EVA wastes, and also the wastes can be reused in colorful ways, similar to punching, which can be used as packaging filling, and hot pressing can be used to make shoe soles. EVA accouterments can be used in electronics, tackle, and toy diligence.

EVA froth formula

EVA raging formula is generally composed of the following raw accouterments main material, padding, raging agent, bridging agent, raging accelerator, lubricant.

main component

The main material is EVA or PE. Of course, to ameliorate the physical parcels of the product, some other accouterments can be added meetly, similar as rubber, POE, etc., and indeed a little TPR can be added to enhance some physical parcels. The main index of EVA is the VA content, and its position is directly related to all the parcels of EVA froth products. Of course. The specific main material used depends on the conditions of the product.

padding

Paddings, presently calcium carbonate or talc are generally used. Its purpose is to reduce costs, increase product severity, etc., and it can also play a part in heat conduction. Generally, the flyspeck size is used as the quality indicator (of course, the water content is also one aspect), similar to 120 mesh, 400 mesh, and so on. In principle, the finer the better, and of course the price will be advanced.

raging agent

Raging agent is generally used as a high-temperature raging agent, and its corruption temperature is further than 220 degrees. There are also low-temperature raging agents with a corruption temperature of 140 degrees and medium-temperature raging agents. Because the price difference isn’t big, and the high-temperature raging agent will be fairly stable, so numerous EVA products now use high-temperature, and some are used in combination. The specific lozenge depends on the specific exaggeration.

bridging agent

Bridging agent, the most used now is DCP (di-sec-octyl phthalate). In general practice, the temperature should be controlled below 120 degrees as much as possible. Some products have conditions on the smell, you can use another bridging agent BIPB, which is generally used in confluence with TAIC. The lozenge of DCP is generally0.5-0.6 Phr in flat plate raging and small in-earth raging, and0.8-1.0 Phr in injection raging. Of course, there are also applicable additions and deductions, and there are also different exercises.

Raging accelerator

There are two kinds of raging accelerators that are more generally used now, zinc oxide greasepaint and zinc stearate greasepaint. A single bone can also achieve the effect, and the stability of the product may be better. Zinc oxide can reduce the corruption temperature of AC to about 160 degrees, which is accessible for products. Generally, if the quantum of zinc oxide is too important, the loss of the product will be fairly large. Of course, if it’s too small, the raging speed is too slow, so it’s stylish not to be lower than1.0 hr/

lubricant

Lubricant, generally stearic acid. It doesn’t have an important effect, it’s to make the material not stick to the machine when training. Using too much isn’t good, because it reduces the disunion between points and reduces most physical parcels.

Three crafts

Generally speaking, there are three kinds of EVA raging processes, the traditional flat large raging process, the small in-earth raging process, and the injection process. Let’s take a look at Xinbodi below!

1. Injection process

This process will gradationally come the mainstream, and the product made in one process is accessible and terse, but the perfection of the earth is fairly high. The process principle is analogous to the injection molding in the plastic assiduity, except that the injection molding is to open the earth incontinently, and the earth temperature is different. The injection of EVA is to acclimate the earth’s temperature of the plastic injection molding and the earth’s opening time. Utmost of the notorious sports shoes now use this system. high effectiveness!

2. Traditional flat large raging process

Now the lower manufactories generally use this process, and the cost of ministry and outfit is fairly low. This process is substantially used to make plates, and also through blanking, edging, and other processes to make products. The raging conditions are fairly fixed, the temperature is 160-170, the time is determined by the consistency of the earth, generally, 90-110 seconds/ MM, and the pressure is 150KG/ square CM.

3. In- earth small raging process

This process is substantially used in shoe accouterments, and sports shoes are used for the first raging of the secondary midsole. Granulate according to the formula, put it into the opened earth, and it’ll be the general appearance after raging. The difficulty is the harmony of the earth and the formula, else it’s delicate to control the exaggeration and hardness at the same time. Frequently the size is good and the hardness isn’t enough, and the hardness is enough and the size is too small. The raging conditions are more flexible, depending on the product structure, of course, substantially due to the influence of time.

Summary: EVA is biodegradable; similar price to PVC; lighter weight; no odor; no heavy metals; no phthalates; high transparency, softness and toughness; super low-temperature resistance (-70C); Resistant to water, salt, and other substances; High thermal bonding; Low bonding temperature; Screen printing and offset printing possible. The future looks bright.