For some people, custom insoles can aid in their path to recovery and improved health. So, do you know how a pair of custom insoles is created?

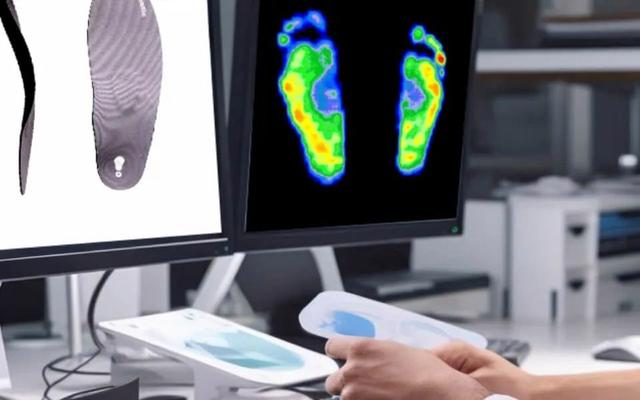

1. The process begins with the scanning of the feet using scanners, static and dynamic pressure sensors, as well as gait analysis through motion capture. This allows for sampling and comprehensive analysis of foot conditions, assessment of force distribution, and identification of biomechanical abnormalities in the lower limbs.

2. A fully functional design software is then utilized to develop correctional design plans based on the diagnosis and specific requirements of the legs.

3. Various modules, materials with different densities, and patented base materials are selected to ensure optimal support and comfort.

4. digital processing enables fast and accurate production, allowing for multiple repetitions of the design plan.

5. A range of surface cover materials is available to cater to correctional needs, aesthetics, moisture absorption, and overall comfort.

6. The insoles undergo meticulous shaping, polishing, and are then packaged for delivery.

7. A customer foot health record is established, and regular follow-up appointments are scheduled to assess the effectiveness of the correctional measures and gather feedback.

The above information outlines the production process of custom insoles. If you are interested in custom insoles, you can continue to visit this page (https://www.aideastep.com/custom-orthotic/) and tell us your needs.