- Model Number

- KE141#

- Function

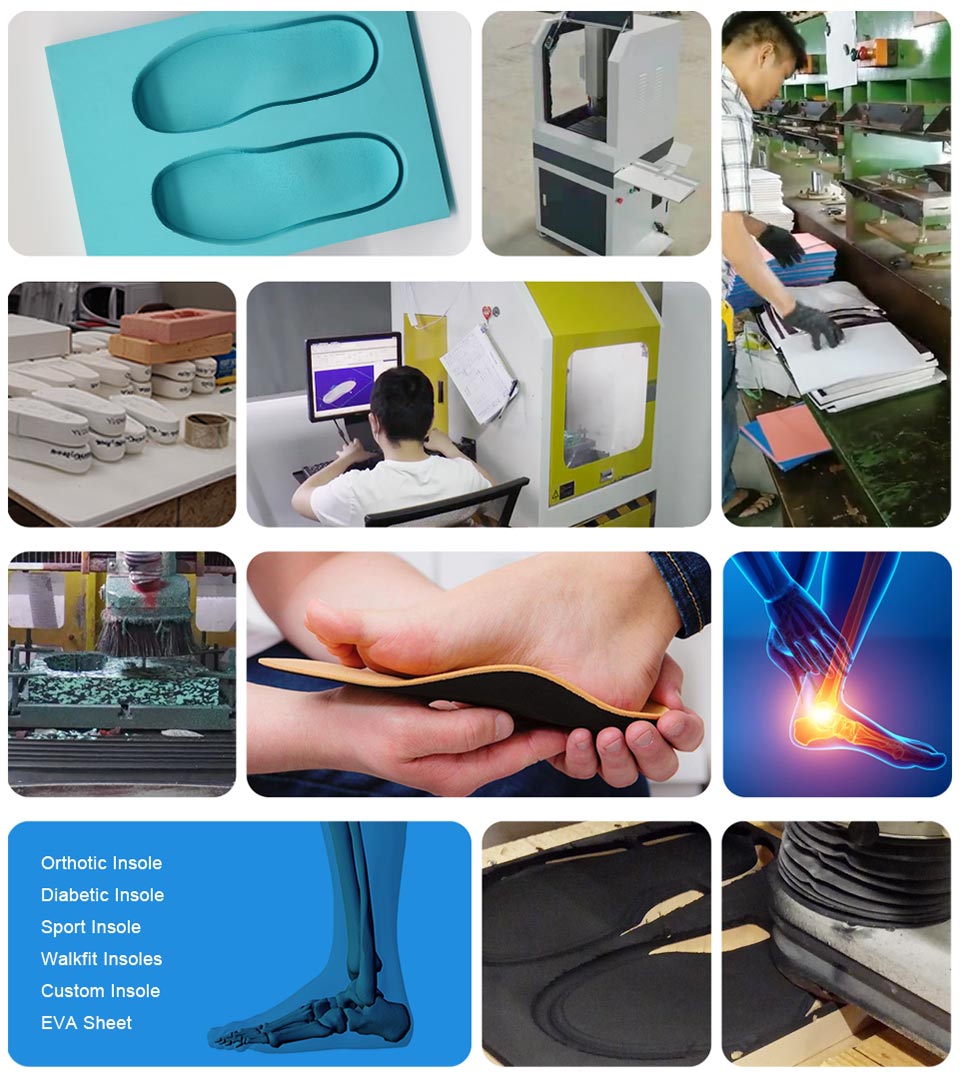

- CAD/CAM Milling eva foam block for custom made Orthotics Insole

- Cooperation

- ODM , OEM and Custom made Available

- MOQ

- 1000prs

- Package

- PP Film

- Price term

- FOB ; C & F , CIF , Door to Door etc.

- Payment terms

- T/T, L/C , Western Union, Paypal etc.

- Delivery time

- 45 days

- Port of Loading

- XIAMEN,FUJIAN,CHINA

- Sample time

- 7 days

- Price

- Get Latest Price

1. The production process of Ideastep is highly mechanized following the international standards. Its transverse arch-shaped design can help release the pressure in sports

2. This well-designed product achieves a fantastic lighting effect that is not only perfect for the ambiance but also good for the people’s mood. It’s shaped to fit the natural contours of the foot structure by the biomechanics design

3. In order to meet its set industry standards, the product is subject to strict quality control throughout the production process. Jointed by hot-melt glue, the product won’t break easily

We mainly customize insoles and EVA sheets. We have leading technology and advanced production equipment, focus on the insole field for more than 20 years, and have the American Medical Council Certification Committee "C.Ped. #4290

|

Type |

Insole material |

|

Brand Name |

IDEASTEP |

|

Place of Origin |

XIAMEN ,Fujian, China |

|

Model No. |

KE141# |

|

Size |

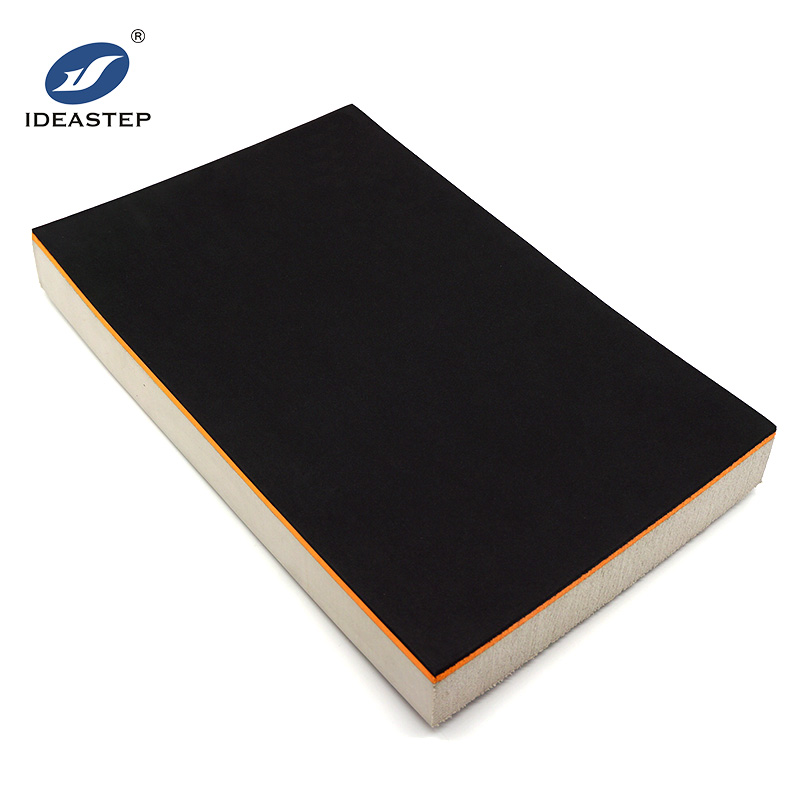

29.4X19X3.5 cm |

|

Color |

Black / orange / grey |

|

Material |

EVA |

|

Package |

As per requirement |

|

MOQ |

1000 Pairs |

|

Feature |

Multi-density combination |

Ideal for CNC milling for custom made Orthotic insole material.

|

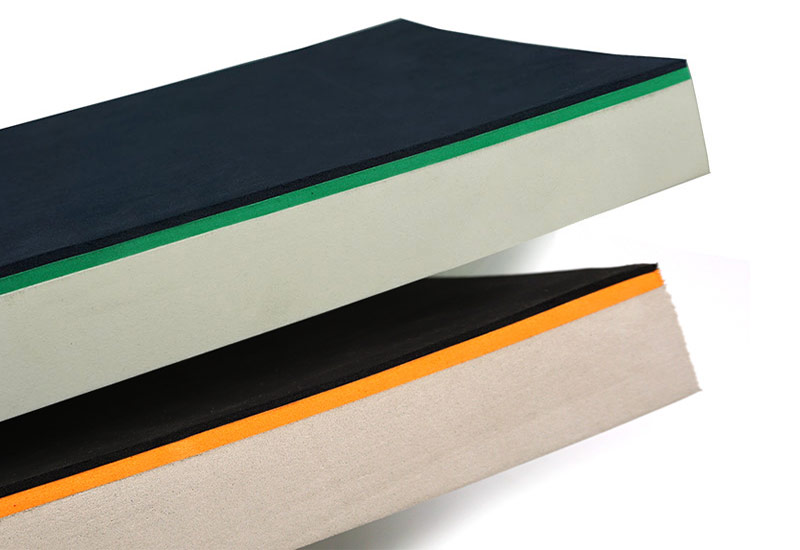

◪ Three density materials are glued together during production process, The secure bonding strength is guaranteed. |

|

◪ It provides permanently stabilizing and cushioning properties. |

Q1: What’s this Eva Block used for?

A1: this Eva Block is the basis for the manufacture of foot beddings and inserts in orthopedic shoe engineering.

Q2: What’s the most benefit of this CNC eva foam?

A2: It’s outstanding edge stability for pressed insoles and has excellent grinding and bonding properties.

Q3: Could I change the hardness?

A3: Yes, EVA hardness can be changed according to your needs.

Q4: Could I get single, dual and triple layers for this kind Eva Block?

A4: Yes, the different layeres can be satisfied.

Q5: What’s the areas of application for this kind Eva Foam block?

A5: It’s good for rheumatism, geriatric foot, diabetes, and a basis for sports inserts.

Company Features

1. Our factory has state-of-the-art manufacturing facilities that introduced from various developed countries. They play a significant role in supporting daily production demands, from product developing stage to the packaging stage.

2. In the days to come, we will continue to adhere to the quality policy of “achieve innovation”. We will continue to meet the needs of our customers, continuously innovate in research and development, and focus on customized product requirements.

Three densities of EVA, 2mm firm Black eva + 4mm Semi-rigid Yellow eva + 30mm soft Beige eva.Triple layers are with closed cell structure and are firmly glued together. They are all with optimally grindable characteristics.The side cutting is in perpendicular guranteed.Colors and specification can be custom made to fit your CNC CAD-CAM milling machines.