Ideastep polyethylene foam vs polyurethane foam goes through a series of production processes: grouting, demoulding, splicing, drilling holes, glaze spraying, and firing which are all carried out by professional workers. The product features a perfect and fine face and shape

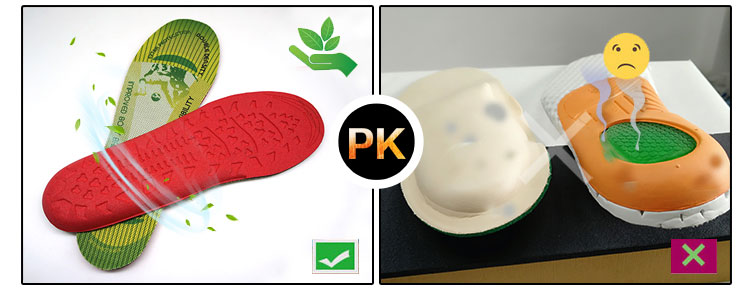

We mainly customize insoles and EVA sheets. We have leading technology and advanced production equipment, focus on the insole field for more than 20 years, and have the American Medical Council Certification Committee "C.Ped. #4290

| Type | Insole material |

| Brand Name | IDEASTEP |

| Place of Origin | XIAMEN ,Fujian, China |

| Model No. | 2#/25# |

| Size | 12*14*3.5*33.5cm |

| Color | Green+Red+blue |

| Material | EVA / As per required |

| Package | 1.Support Inserts packed in OPP bag 2.Depend on buyer request |

| MOQ | 1000 Pairs |

| Feature | A better functionging material can be achived |

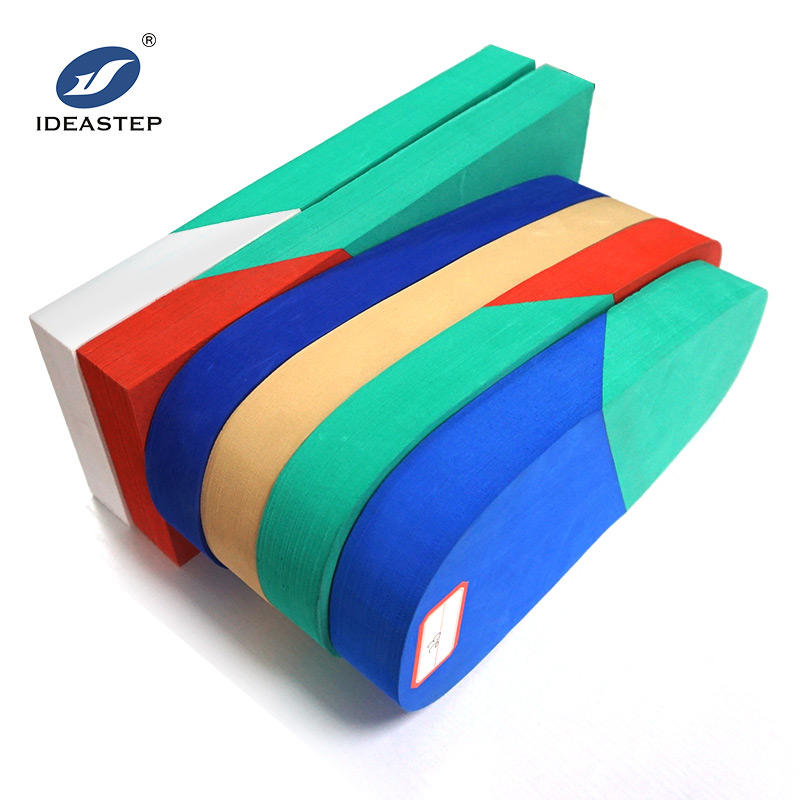

Single Density Duck Eva Blocks

Our products are corrective insoles, medical orthopedic equipment, and adequate disease in the big health industry. We divide our products into seven categories: orthopedic insoles; sports insoles; insole for diabetic foot; thermoplastic orthopedic insoles; daily Insole used; women's insoles; children's insoles and more.

Widely used in a variety of sports, leisure and ankle correction.

|

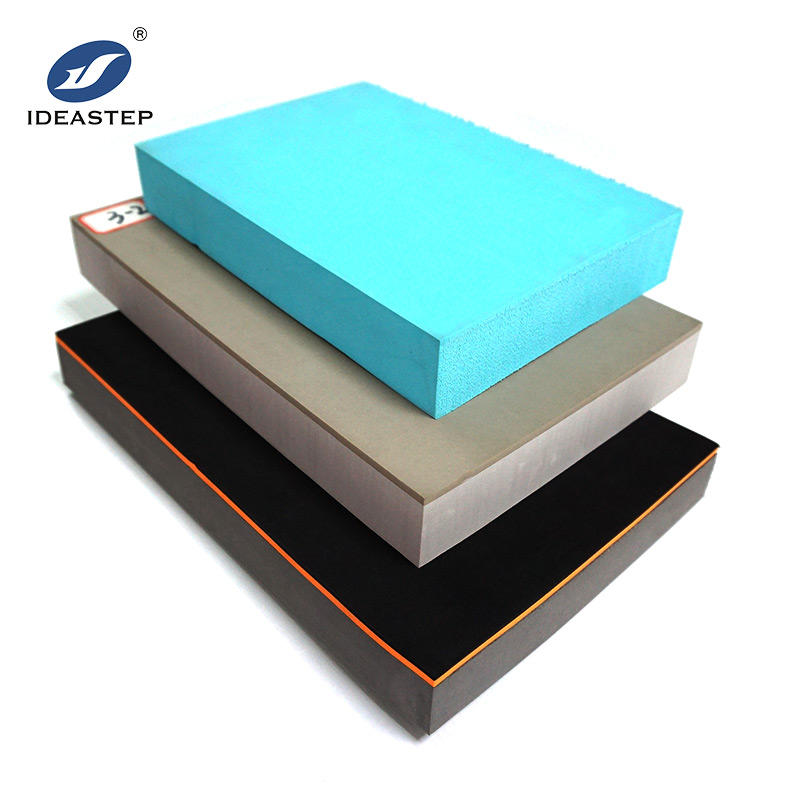

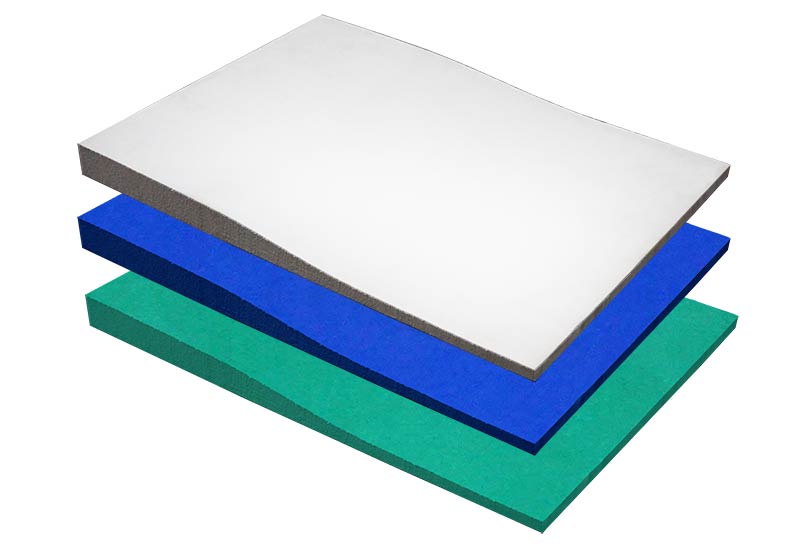

◪ These pre-laminated or pre-skived EVA Foam Sheets provides the permanent resilience and stabilisation base for orthopaedic Insole. |

|

◪ They’re the grindable Eva Materials to fabricate custom made foot orthoses quickly and easily. |

|

◪ Specifically developed for milling in cooperation with foot orthotic cad cam manufacturers. |

Q1: Can you let us know your full range of Eva Blocks ?

A1: Our Eva Blocks incluidng:

– The cad-cam Single 、Dural and Multi-densities eva blocks in joint or lamination ;

– Insole Top Covering materials in different kinds cushioning foam

– Profile Strip blocker by different dimensions and hardness

Q2: Can you make the Eva Blocks in the specific sizes to fit my CAD-CAM milling Machine?

A2: Yes,following your requirments,the Custom combinations in sizes thickness and colores are available to be made.

Q3: What’s the production Lead time for your Eva Foam Materails production.

A3: The L/T is 20-30 days.

Q4: Have your Eva Milling Blocks approved any CADCAM Foot Orthotics Manufacturers?

A4: Yes, the CADCAM Foot Orthotics Manufacturers located in North Amercia Europe have used these blocks for over 8 years and give us good response.

Q5: How about your lamination quality for the dual or Multi lamination Eva Materials?

A5: Pls be sure the lamination quality is perfect and we use the Environmental glue to join them together.

An excellent Eva material for CAD-CAM foot orthotic,we offer higher density for more control and lower densities for comfort.The higher density and Lower density joint together to milling Orthotic by heel control and Forefoot comfort in the meantime.Provide a better function by different characteristics materials laminated together for CAD-CAM milling Orthotics.The pre-skived Eva Sheets to make custom Orthotic Insole more convenience. The cost down not only in Blocks itself but also from the inventory,space and processing time in working.