3D custom-made insoles, also known as 3D printed insoles, are orthotic devices that are specifically designed and manufactured using 3D printing technology to provide personalized support and comfort. Here is how the process typically works:

1. Foot Scanning

The first step involves scanning the individual’s feet using a specialized scanner or app. This creates a digital model of the foot, capturing its unique shape and contours.

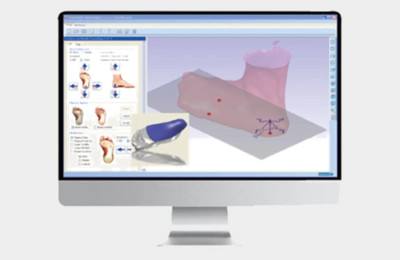

2. Design customization

Using computer-aided design (CAD) software, orthotics or podiatrists can customize the design of the insole according to the individual’s specific needs. They can adjust arch support, heel cup depth, metatarsal pad placement, and other features based on factors such as foot structure and any existing conditions like plantar fasciitis or flat feet.

3. 3D printing

Once the design is finalized, it is sent to a 3D printer where layers of material (usually thermoplastic polyurethane or TPU) are deposited one on top of another until a complete three-dimensional insole is formed.

4. Finishing touches

After printing, any necessary post-processing steps may be performed. Such as smoothing rough edges or adding cushioning materials for additional comfort.

The resulting 3D custom-made insoles are tailored precisely to fit an individual’s feet anatomy, providing superior support for arches. Proper alignment for joints, shock absorption properties based on activity levels, and reducing pressure points that can lead to discomfort or pain during walking or running activities.

Expand more related content: https://www.aideastep.com/custom-orthotic/.